In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Weighing and filling machine

Introduction of equipment

| Introduction of equipment | Automatic in-line intelligent weighing and filling machine integrates machine, light, electricity and gas. It is controlled by computer program. It has weighing type, volume type and so on.Loading mode. High precision and range of use, independent of material temperature, density, viscosity, gas content and other external factors, with high precision weightDetection mode, automatic barrel entry, automatic peeling, automatic submergence, automatic filling, automatic lifting, automatic output. The fish can be widely used in various oils and fats.Chemical, pharmaceutical, food and other industries. |

| Equipment features |

1. The machine adopts Siemens weighing system and precision mechanical system; electrical components adopt Siemens PLC, man-machine, servo motor, etc., filling capacity.It can be set quickly in man-machine. 2. The seals are made of imported PTFE sealing rings, which can withstand strong acid and alkali, and can be used in high temperature environment. Meet physiological safety requirements.It is used for food and medicine seal, it does not contain smell and taste, and is suitable for food contact. 3. All parts in contact with materials are made of imported food grade stainless steel and processed by NC machine tools. The cylinder block for filling is made of SUS316#.The unique filling valve design effectively avoids the leakage of liquid. 4. Introduce the advanced design concept of clamp type in Europe to realize quick disassembly, cleaning and maintenance without any special tools and meet the requirements of GMP. 5. lateral bottle mouth positioning system further ensures bottle mouth positioning. 6. fault automatic inquiry and display, material super liquid alarm function. 7. Moving up and down filling of workstation can effectively prevent foaming; advanced man-machine interface operation can steplessly adjust production speed |

| Video link |

| technical parameter | |||

| Production speed | 6-8 buckets / minutes (2 heads for example) | Number of filling head | 2-12head |

| Filling Precision |

0.5% |

Filling range | 5kg-50kg |

| Use of electricity | 220V 50Hz 5000W | air source | 0.8Mpa |

| Whole machine size | L1650×W1810×H2200 mm | Gas consumption | 0.3-3 L/min |

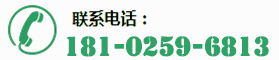

Filling machine

Filling machine Labeling machine

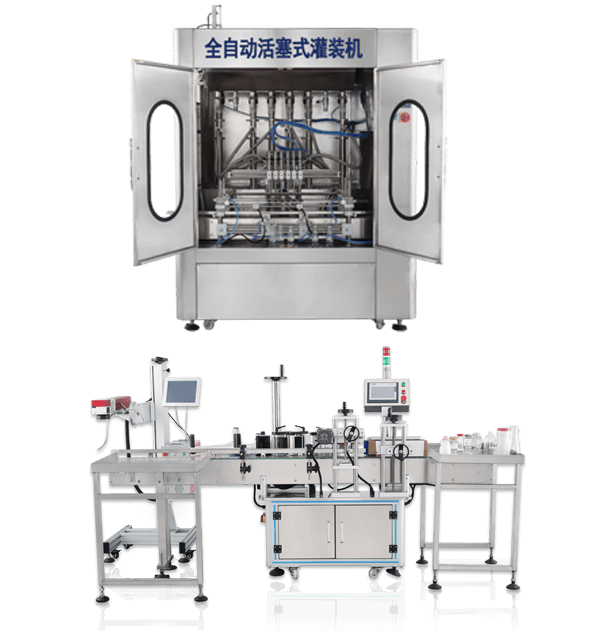

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..