In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Four pieces of gel tube, automatic tube filling and pressing cap machine.

Overview of equipment:

This equipment is controlled by pneumatic and electrical integration and PLC system, easy to operate, is the most ideal combination of gel tube equipment in line with the domestic GMP production specifications, effectively avoiding the secondary pollution caused by manual assembly.

Some technical parameters of assembly pipe:

Suitable size: four piece gel tube or flat tube.

The form of the plug: electromagnetic vibration disk plug.

Tamper form: cylinder plug.

Assembly station: 2 stations.

Production speed: 1500-1800 PCS / HR

Whole machine power: about 2KW

Program control: PLC with touchscreen man-machine interface

Main material: the rack is made of 304 stainless steel, and the material contacting with the material is 304# stainless steel.

Air pressure: 0.6-0.8MPa

Power supply: AC220V or 380V 50/60HZ

Technical parameters of filling part

The equipment is controlled by pneumatic and electrical integration and PLC system, easy to operate, and is the most ideal gel filling equipment in line with the domestic GMP production specifications. The equipment adopts servo piston type quantitative filling, which has high filling precision and can minimize the bubbles in the gel itself to achieve beautiful results. At the same time, the equipment can also fill thin materials and thick materials, effectively solve the trouble that OEM / ODM can not fill thick materials.

Technical parameters:

Filling heads: 2

Number of bottom covers: 2

Number of gland heads: 2

Suitable for bottle type: four piece gel tube or flat tube.

Filling capacity: 3~5 grams

Filling form: servo drive piston quantitative filling.

Cap type: electromagnetic vibrating disk (different sizes need to replace vibrating disk and guide).

Lower cover form: pneumatic lower cover

Gland type: pneumatic gland

Production speed: 1300-1600 bottles / hour

Filling accuracy: + 1%

Whole machine power: about 2KW

Program control: PLC with touchscreen man-machine interface

Main Material: The frame adopts 304 # stainless steel, and the material contact part material is 304 # stainless steel, silica gel tube.

Material tank capacity: about 30L

Air pressure: 0.6-0.8MPa

Power supply: AC220V 50/60HZ

Equipment size: L2700 * W1300 * H1500mm

(the above equipment is also suitable for the packaging of four sleeves, such as light needle and other products).

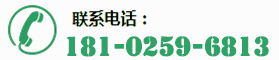

Filling machine

Filling machine Labeling machine

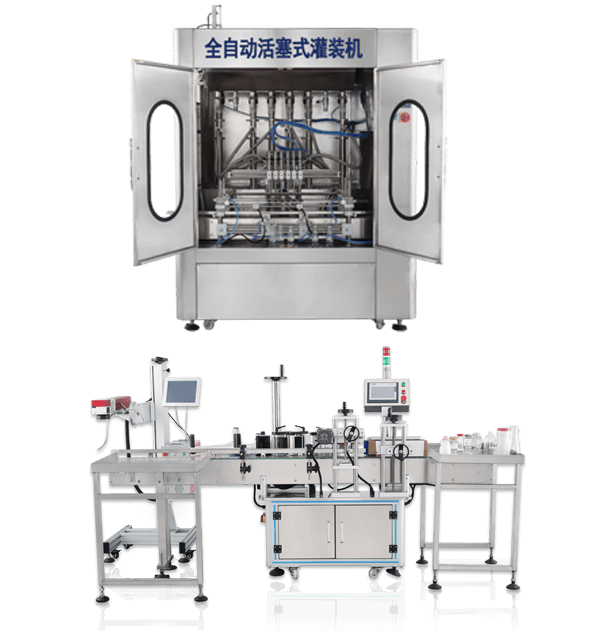

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..