In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Automatic filling machine maintenance

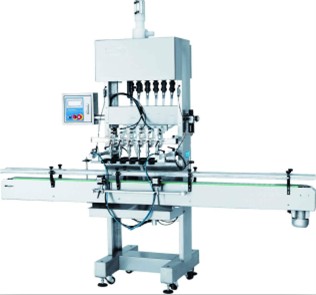

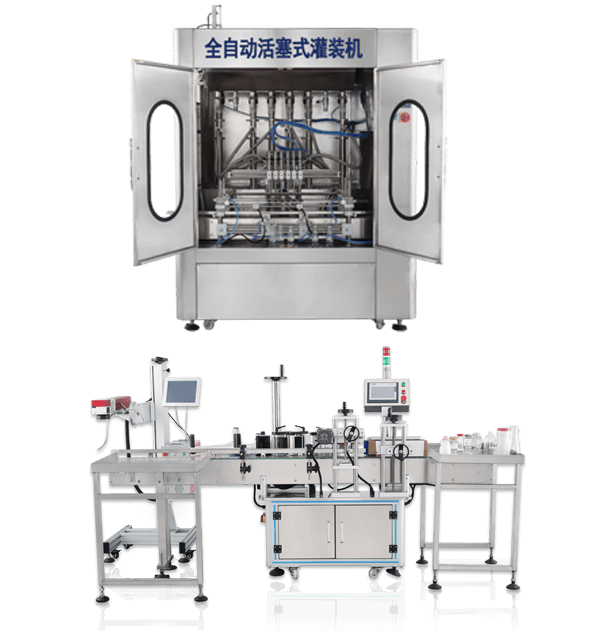

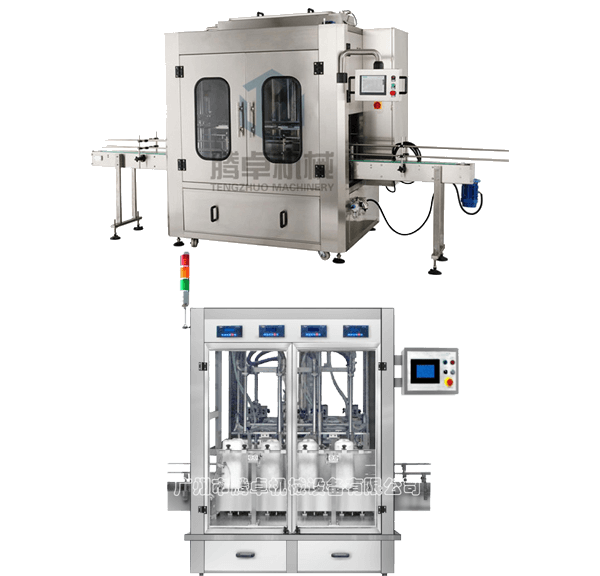

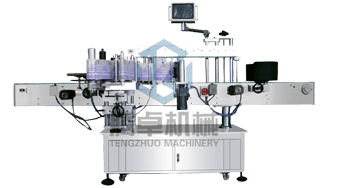

Fully automatic filling machinery is the filling of objects, belongs to the category of packaging machine, from the production automation degree is divided into semi-automatic filling machine and fully automatic filling production line; From the Angle to the packing of the material can be divided into liquid filling machine, paste filling machine, powder filling machine, granule filling machine. Recently as the food QS certification, edible oil manufacturers have begun to pay attention to product quality and packaging, so the oil filling ‘status in the bottling industry. Guangzhou zhuo teng machinery equipment co., LTD. Is mainly research and development production of various kinds of semi/full automatic filling machine, including liquid filling machine, oil filling machine, paste filling machine. We has a wealth of experience in the field of fluid packaging, both water and cream products, whether high bubble or corrosive products, we can choose the most reasonable solution for you.

做好日常维护的步骤有:

Do daily maintenance steps are:

1. Before going to work every day to observe pneumatic combination of dual water gas and oil mist filter, such as too many water should be ruled out in time, the oil level should be timely enough fuel.

2. Always observing in the production of mechanical parts, whether rotation, lift is normal, without exception, have screw without loose.

3. Regularly check equipment ground, contact requires reliable; Often clean the weighing platform; Check whether there is any leakage on the pneumatic pipe, whether tracheal rupture.

4. If when not in use for long time, to put the pipe material emptying, keep the machine dry.

5. To do a good job of cleaning and hygiene, keep the machine clean surface, often clear the product material on the balance of body, pay attention to keep clean in electric control cabinet.

6. Sensors are tightness, high sensitivity, high accuracy and it is strictly prohibited to hit and overload, and may not contact, in the working process of access to this device may not be moved.